Acqualatina Arsenic Removal Plants, 82.000 m3Jday Aprilia (LT), ITALY

Groundwater in the southern Lazio region features arsenic concentration above the limits allowed by European and Italian legislation. Legislative amendments introduced in 2001 have affected the municipalities of certainareas of Italy, which, in turn, have been forced to make operational specific water treatment plants for the removal of this pollutant. Accordingly, Acqualatina S.p.A. the local water distribution company, has implemented a plan to deal with arsenic in the Latin area, requiring an investment of 17 million Euro, a substantial financial commitment, whichallowed the installation of as many as 9 arsenic removal plants and the construction of a tt km-long water pipeline, permitting the distribution of drinking water from Ninfa to Cisterna di Latina.

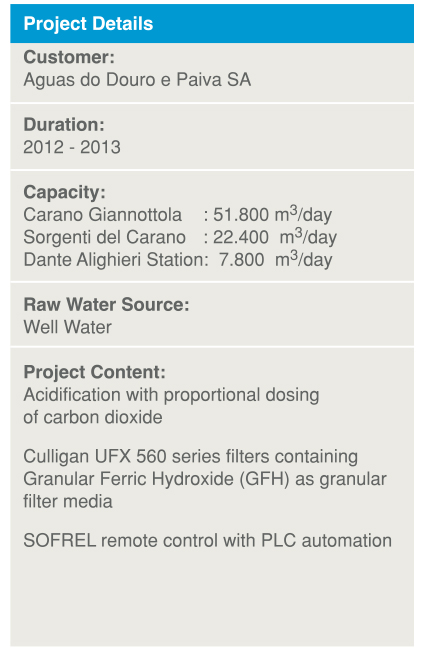

ProJect Details

Culligan provided Acqualatina with a complete solution to remove arsenic from drinking water, installing and commissioning three arsenic removal plants in the following locations:

- Carano Giannottola (Municipality of Aprilia, in the province of Latina): flow capacity of 900 m3Jday

- Sorgenti del Carano {Municipality of Aprilia, in the province of Latina): flow capacity of 300 m3/d

- Dante Alighieri Station (municipality of Cisterna di Latina, Latina): flow capacity of 800 m3Jday

Culligan provided comprehensive services, ranging from preliminary design to final testing, as well as a 3-year management plan. Arsenic removal plants in the aforementioned areas are necessary to ensure the permanent solution of issues relating to arsenic in groundwater. Culligan’s solution proved to be particularly robust, since its goal was to manage the arsenic fluctuations in water, even in the face of strong variations in the amounts of water collected, and, in particular, during summer or, in any case, during eriods of high consumption. The installed plants perform arsenic removal by relying upon a process of adsorption on iron oxide-hydroxide-based GFH (Granular Ferric Hydroxide) mineral, with direct filtration (without any need for additional intermediate pump stations, and, thus, reducing energy consumption). Water is collected from aquifers and sent directly to 4 filtration lines, each consisting of 4 filters arranged in a cloverleaf configuration. The system does not use chemical products, with the exception of carbon dioxide required for the arsenic removal process, and sodium hypochlorite for disinfection, and, therefore, operating costs are minimized.

With the commissioning of these facilities, the arsenic problem was resolved permanently throughout the affected geographical areas within the limits imposed by EU legislation.